making led neon signs

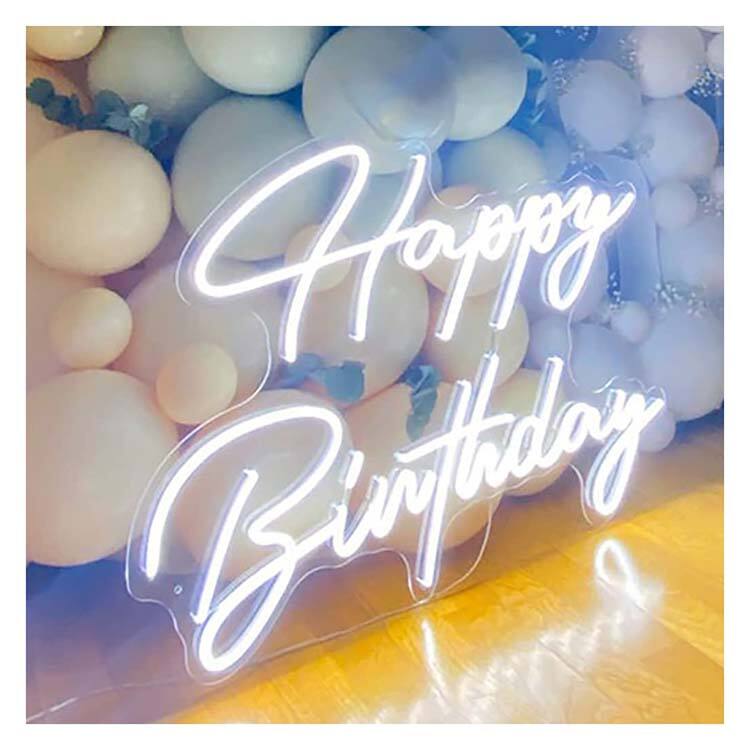

Making LED neon signs represents a revolutionary advancement in modern signage technology, combining the classic aesthetic appeal of traditional neon with cutting-edge LED innovation. These sophisticated illumination systems utilize flexible LED strips encased in specialized silicone tubing to create smooth, continuous lighting effects that closely mimic the appearance of conventional glass neon tubes. The manufacturing process involves precision engineering, where individual LED chips are mounted on flexible circuit boards and then protected by weather-resistant silicone housing. The main functions of making LED neon signs include providing vibrant, customizable lighting solutions for commercial advertising, architectural accent lighting, decorative installations, and informational displays. The technological features encompass low voltage operation typically ranging from 12V to 24V DC, programmable color-changing capabilities through RGB or RGBW configurations, dimming controls, and integration compatibility with smart lighting systems. Modern LED neon manufacturing incorporates advanced thermal management to ensure consistent performance and extended operational lifespan. The production process also includes quality control measures such as waterproof ratings up to IP67, ensuring reliable performance in various environmental conditions. Applications span across retail storefronts, restaurant signage, hotel lobbies, entertainment venues, residential accent lighting, automotive detailing, trade show displays, and architectural highlighting. The flexibility of making LED neon signs allows for intricate curved designs, sharp corners, and complex geometric patterns that would be impossible or extremely costly with traditional glass neon. Manufacturing techniques have evolved to include seamless connection systems, allowing for continuous runs without visible joints or interruptions in the lighting pattern. The technology also supports various control methods including manual switches, remote controls, smartphone applications, and integration with building management systems for automated operation.