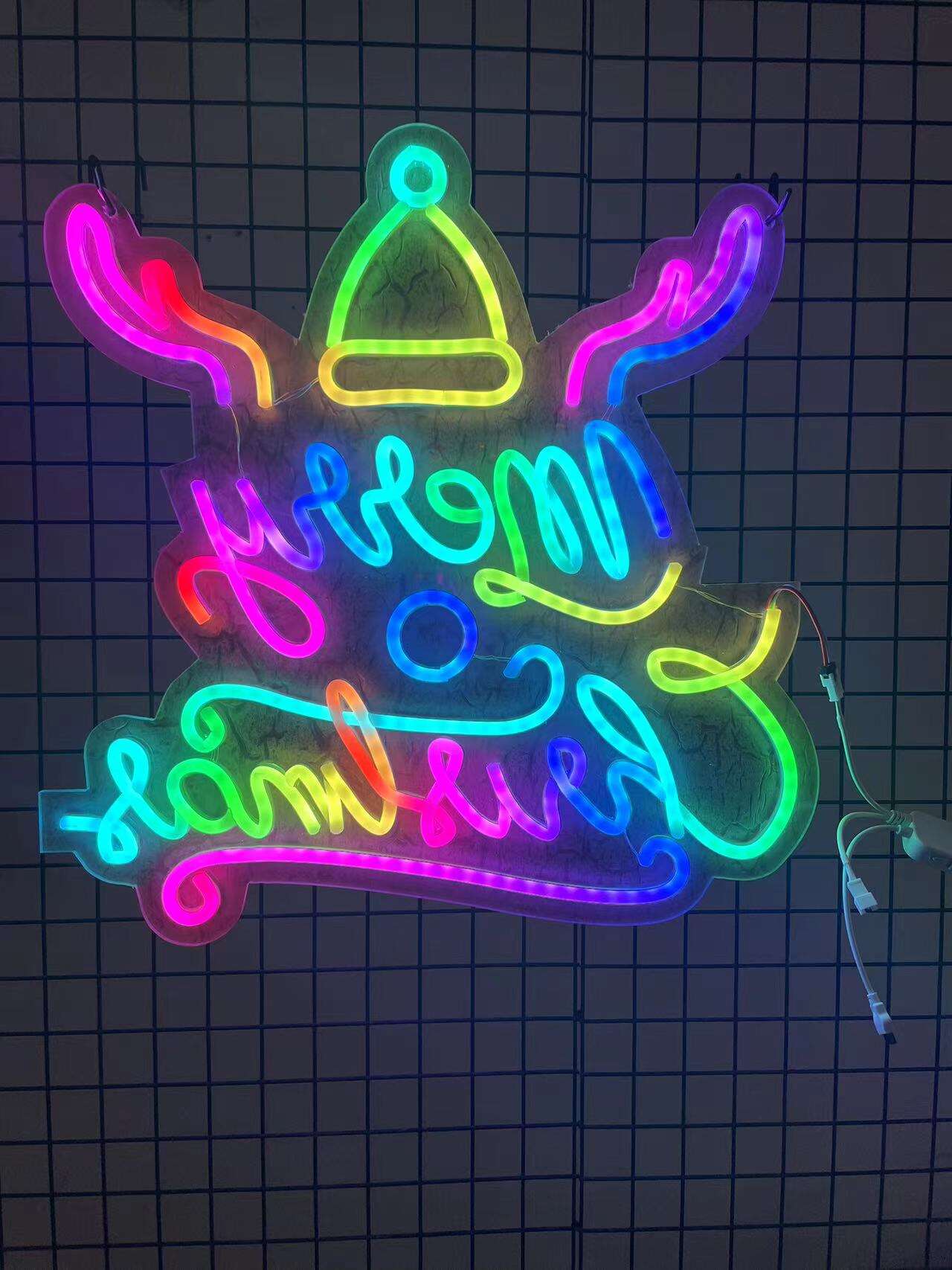

Exceptional Flexibility and Design Versatility

The remarkable flexibility of neon flex light technology revolutionizes how lighting designers and architects approach illumination projects, offering unprecedented creative freedom that traditional rigid lighting systems cannot match. The advanced silicone construction of neon flex light products enables smooth bending around corners, curves, and complex architectural features without compromising light quality or creating visible joints that disrupt visual continuity. This flexibility extends beyond simple curves, allowing neon flex light installations to follow intricate patterns, outline building facades, and create custom shapes that enhance architectural aesthetics. The cutting radius capabilities of modern neon flex light systems typically range from 10mm to 50mm depending on the specific product configuration, providing designers with precise control over installation geometry. Professional installers appreciate how neon flex light products conform to irregular surfaces and navigate tight spaces that would be impossible to illuminate with conventional lighting methods. The seamless appearance achieved through neon flex light technology eliminates the segmented look associated with traditional LED strip lighting, creating uniform illumination that mimics the smooth glow of classic neon while providing superior performance characteristics. Color-changing neon flex light variants add another dimension of versatility, enabling dynamic lighting displays that can transform spaces for different events, seasons, or branding requirements. The ability to cut neon flex light products at designated intervals allows for precise length customization, ensuring perfect fits for any application without waste or compromise in appearance. Weather-resistant formulations of neon flex light products extend this versatility to outdoor applications, where the flexible design enables illumination of landscape features, building perimeters, and decorative elements that require weather-proof lighting solutions. Integration capabilities with smart control systems further enhance the versatility of neon flex light installations, allowing for programmable effects, synchronized displays, and remote management that adapts to changing requirements. The low-profile design of neon flex light products facilitates concealed installations where traditional lighting fixtures would be intrusive, enabling accent lighting that highlights architectural details without visible hardware. Manufacturing advances in neon flex light technology continue to expand flexibility options, with new formulations offering enhanced bend radius capabilities and improved durability for demanding architectural applications.