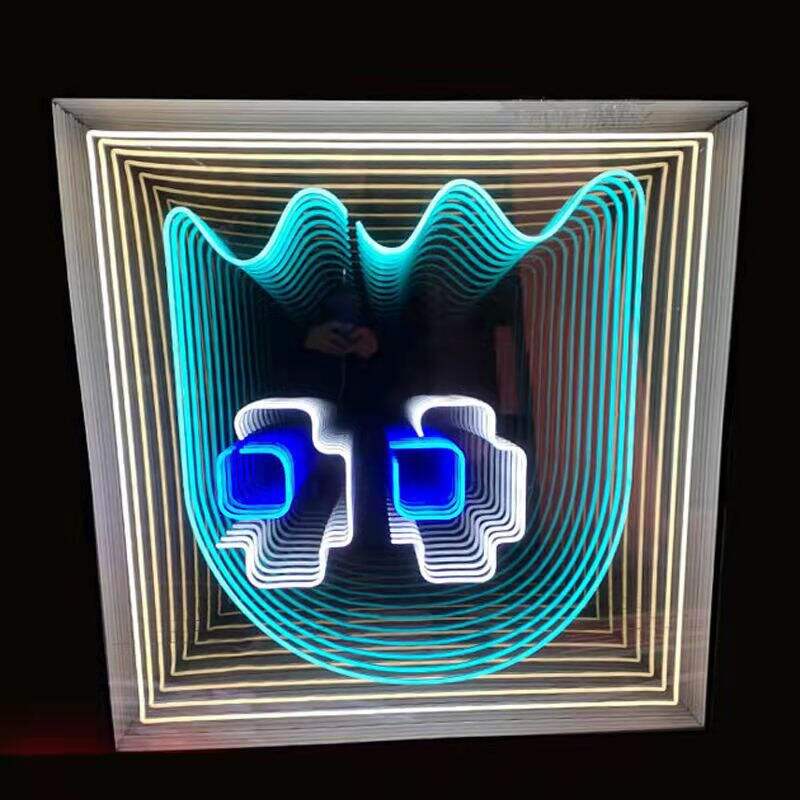

laserskurna akrylskyltar

Laserklippta akrylskyltar representerar en sofistikerad kombination av modern teknik och mångsidiga designmöjligheter, vilket gör dem till en viktig lösning för samtida skyltbehov. Dessa skyltar använder laserskärningsteknik med hög precision för att skapa detaljerade mönster, former och texter i kvalitetsakryl, vilket ger exceptionell klarhet och ett professionellt utseende. Laserskärningsprocessen använder fokuserade ljusstrålar för att uppnå anmärkningsvärt rena kanter och exakta mått, vilket eliminerar de ojämna ytor som ofta förekommer vid traditionella skärmetoder. Akryl, även känt som plexiglas eller PMMA, är det främsta material som används på grund av sina utmärkta optiska egenskaper, väderbeständighet och hållbarhet. De tekniska egenskaperna hos laserklippta akrylskyltar inkluderar datorstyrd precision som möjliggör komplexa geometriska mönster, anpassade teckensnitt och detaljerade logotyper med mikroskopisk noggrannhet. Laserstrålens intensitet kan justeras för att skapa olika effekter, från fullständiga skärningar till ytgravering, vilket ger flera designalternativ inom ett och samma objekt. Dessa skyltar behåller sina levande färger och strukturella integritet under olika miljöförhållanden, vilket gör dem lämpliga för både inomhus- och utomhusinstallationer. Tillämpningarna omfattar många branscher, inklusive butiker, kontorslokaler, vårdinrättningar, utbildningsinstitutioner, restauranger och offentliga platser. Företag använder laserklippta akrylskyltar för butiksfrontsvisning, riktningssystem, säkerhetsmeddelanden, reklammaterial och arkitektoniska element. Mångsidigheten sträcker sig även till bostadsanvändning där hushåll använder dessa skyltar som adressskyltar, dekorativa paneler och personliga displaylösningar. Tillverkningsanläggningar drar nytta av tekniken som möjliggör konsekventa resultat i stora serier samtidigt som individuell anpassning bevaras. Den precisionsstydda skärprocessen säkerställer att varje skylt uppfyller exakta specifikationer, vilket stödjer professionella varumärkesinitiativ och efterlevnad av regelkrav i mångskiftande kommersiella miljöer.